Custom Extruded Aluminum Soldering IGBT Heatsink Thermal

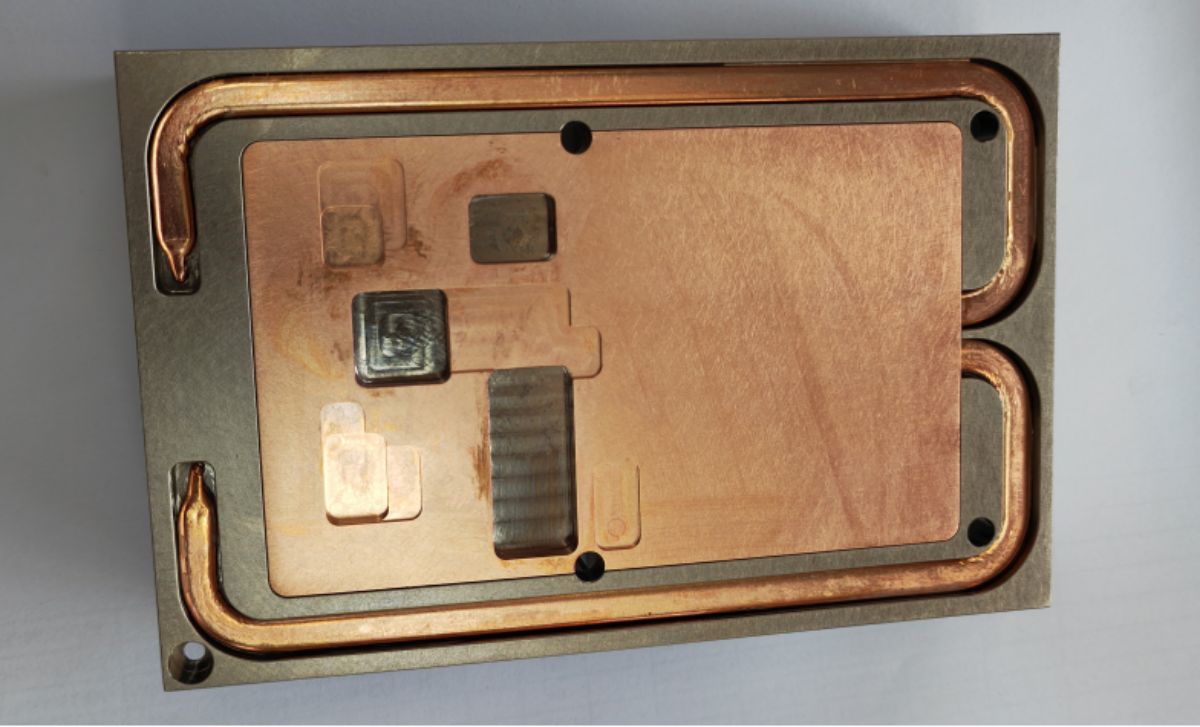

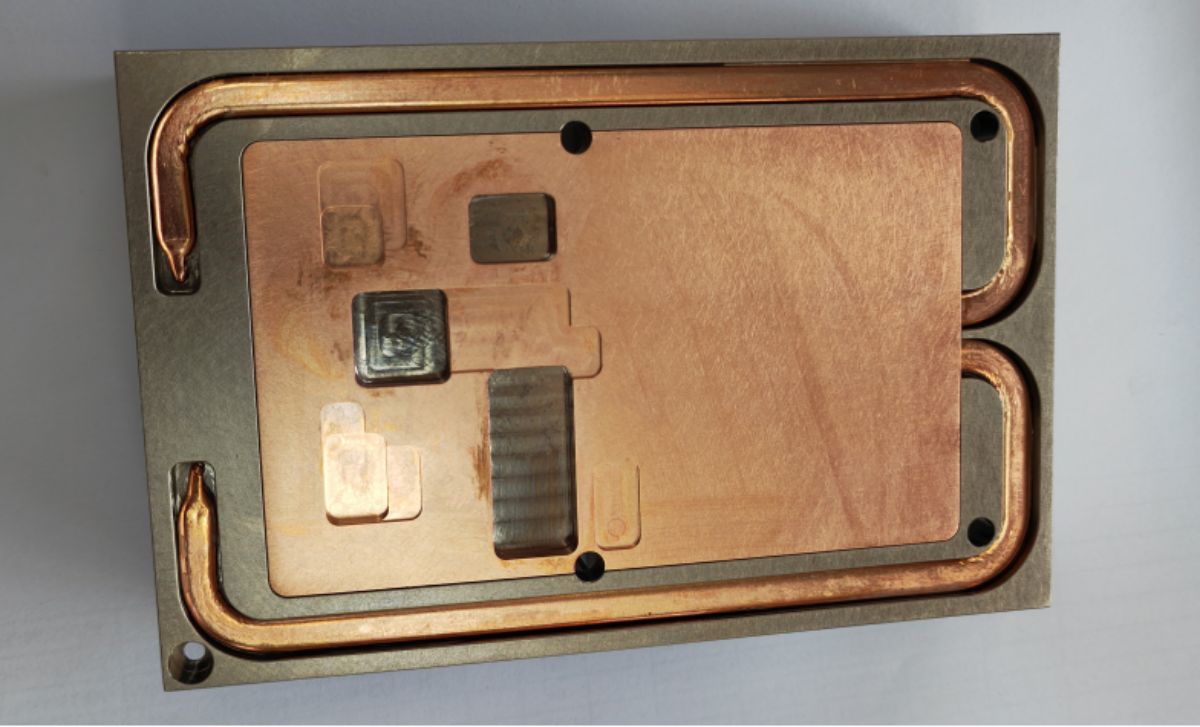

IGBT Heat Sink

The most common IGBT heat transfer modes are copper or aluminum heat sinks, air cooling, and water cooling. The fundamental idea of heat transfer underlies its heat dissipation; a heat flow path with the lowest thermal resistance is created for the device in order to maximize heat emission and guarantee that the internal junction temperature of the device is always maintained within the permitted junction temperature.

Because of its high switching frequency, buffer circuit absence, easy protection, and excellent reliability, IGBT heat sinks are becoming increasingly important in the electronic market. Numerous integrated circuit methods, including fine lithography, ion implantation, and epitaxy, were employed to attain this high performance levels. Power IGBT module heat sink performance has increased significantly in recent years; it can now sustain voltages of over 1500V and have rated currents of hundreds of amperes.

The p-channel power IGBT module heat sink's characteristics are similar to those of the n-channel IGBT because IGBT devices have positive PIN diode characteristics. This makes it easy to adopt complementary structures in applications, which broadens the devices' use in the field of ac and digital control technology. IGBT's ability to tolerate current shock in both the on and short circuit states is its greatest feature. Its short shutdown latency makes its series connection simple and its parallel connection trouble-free.

We provide custom designs in addition to our conventional heatsinks to satisfy our clients' unique needs. Together, you and our skilled engineering team may create a unique heatsink that satisfies all of your requirements.

For additional information, contact us(https://www.cncyaotai.com/contact-us/) right now!