Factory For Old Metal Brake - Aluminum Die Casting Parts for Machinery Part – Yaotai

Factory For Old Metal Brake - Aluminum Die Casting Parts for Machinery Part – Yaotai Detail:

Aluminium Die Casting is a casting process whereby molten aluminium is injected at high pressure into a steel mould in order to achieve a specific net shape. Further secondary processes can be performed if necessary.

Die casting is widely used by many engineers and manufacturers due to the ability to create a wide number of high-strength, intricate parts at continuous high speed, reducing part cost.

Yaotai has excellent capability to produce Aluminium Die Cast parts. By having the ability to produce both complex steel moulds and the aluminium parts themselves, our prices remain extremely competitive and lead times can be reduced.

Our clients choose Yaotai for the wide suite of manufacturing processes on offer. If you’re looking for Aluminium Die Cast parts with a subsequent machining operation or finishing process, Yaotai has the capability to provide it under one roof.

We’re also ISO 9001 certified which ensures we deliver high-quality parts on time and to specification.

With our focus on excellent and responsive customer service, trust Yaotai to make your manufacturing project simple, straightforward and streamlined.

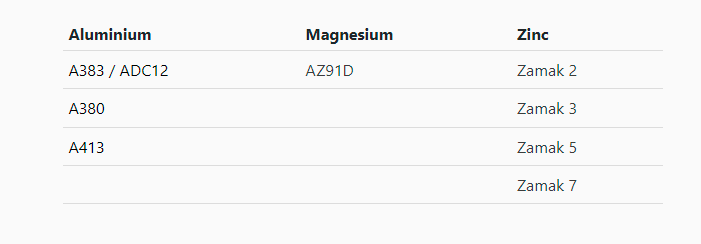

Aluminium is the most common material for high-pressure die casting, however, we can also cast Magnesium and Zinc. If you require a specific grade not listed here, please do contact us to discuss your requirements.

Product detail pictures:

Related Product Guide:

We know that we only thrive if we can guarantee our combined price tag competiveness and top quality advantageous at the same time for Factory For Old Metal Brake - Aluminum Die Casting Parts for Machinery Part – Yaotai , The product will supply to all over the world, such as: Casablanca, Sierra Leone, Venezuela, After years' creating and developing, with the advantages of trained qualified talents and rich marketing experience, outstanding achievements were gradually made. We get good reputation from the customers due to our good solutions quality and fine after-sale service. We sincerely wish to create a more prosperous and flourishing future together with all the friends home and abroad!

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.