CNC machining is a versatile and cost-effective manufacturing process. This process is compatible with a huge range of materials. As such, CNC machining helps across a diverse array of industries for a variety of applications. Manufacturers and machinists use this process in various ways. This includes direct manufacturing process, indirect manufacturing process, or in conjunction with other processes.

As with any manufacturing process, the unique advantages of CNC machining inform the kind of applications for which it can be used. However, the benefits of CNC are desirable in virtually any industry. They are suitable for many parts and products. Since CNC machines can process almost any type of material, their applications are near limitless.

From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining. Let’s get straight to it!

Industries That Use CNC Machining

CNC machining prototype productions are not tied to any single sector. People use it virtually everywhere. It helps to create everything from aircraft parts to surgical tools. We can, therefore, characterize the applications of CNC machining in different industries. The following industries gain from CNC machining purpose:

Aerospace Industry

The aerospace industry has a long-shared history with CNC machining. The machining of metal aircraft components occurs at the highest level of precision. This is highly essential for safety-critical applications. Also, the range of engineering metals compatible with CNC provides aerospace engineers with plenty of options.

The applications of CNC machining in the aerospace industry are wide and reliable. Some of the machinable aerospace components include engine mounts, fuel flow components, landing gear components, and fuel access panels.

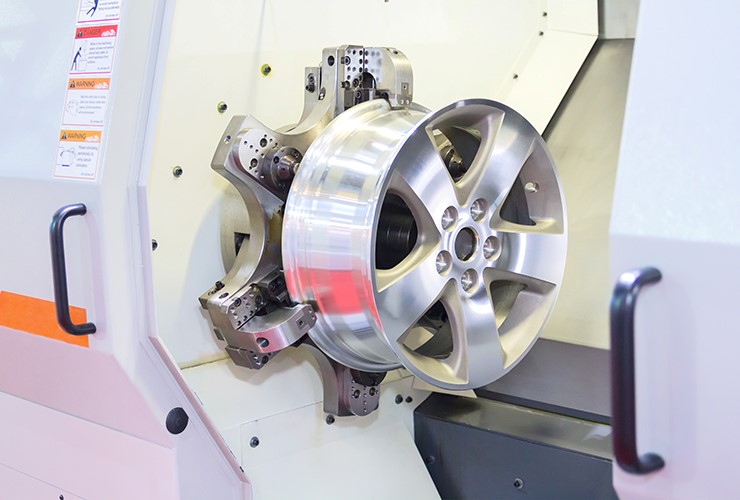

Automotive Industry

The automotive industry regularly enjoys the uses of CNC milling machine for both prototyping and production. Extruded metal can be machined into cylinder blocks, gearboxes, valves, axels, and various other components. On the other hand, CNC machines plastics into components like dashboard panels and gas gauges.

CNC machining in the automotive industry is also useful for creating one-off custom parts. The creation of various replacement parts is also possible with CNC. This is because the turnaround times are fast, and there is no minimum required part quantity.

Consumer Electronics

CNC machining also helps in the prototyping and production of consumer electronics. These electronics include laptops, smartphones, and many others. The chassis of an Apple MacBook, for example, comes from the CNC machining of extruded aluminum and then anodized.

In the electronics industry, CNC machining helps to create PCBs, housings, jigs, fixtures, plates and other components.

Defense Industry

The military sector frequently turns to CNC machining for the prototyping of rugged and reliable parts. The intention of the machining is to allow the parts to withstand wear and tear with minimal upkeep.

Many of these parts overlap with other industries such as aerospace and electronics. The ability of CNC machines to provide on-demand replacement parts and upgraded components are particularly useful in this industry. Therefore, it works well for parts that demand constant innovation and security.

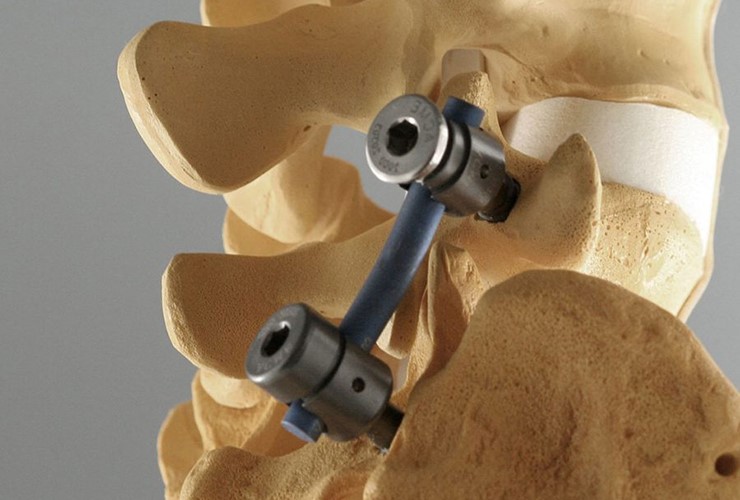

Healthcare Sector

CNC machining offers its use on various medically safe materials. Since the process is suited to one-off custom parts, it has many applications in the medical industry. The tight tolerances afforded by CNC machining are essential to the high performance of machined medical components.

CNC machinable medical parts include surgical instruments, electronic enclosures, orthotics, and implants.

Oil & Gas Industry

Another industry that requires tight tolerances for the safety-critical application of CNC lathe is the oil and gas industry. This sector leverage the uses of CNC milling machine for precise, reliable parts such as pistons, cylinders, rods, pins, and valves.

These parts are often used in pipelines or refineries. They may be required in smaller quantities to fit specific quantities. The oil and gas industry often requires corrosion-resistant machinable metals like Aluminum 5052.

Post time: Mar-04-2022