Short Lead Time for Metal Tumbling Machine - Aluminum OEM Stamping Sheet Metal Fabrication Part For Telecom – Yaotai

Short Lead Time for Metal Tumbling Machine - Aluminum OEM Stamping Sheet Metal Fabrication Part For Telecom – Yaotai Detail:

Sheet Metal Fabrication is an economical manufacturing solution for low to high volume steel and aluminium parts. Yaotai offers professional sheet metal fabrication services for sheet metal parts with no Minimum Order Quantity (MOQ). With a competitive turnaround time, we can you with the flexibility to order the parts you need, when you need them.

Our partner factories have strong capacity and use state-of-the-art equipment to manufacture your bespoke sheet metal parts. With a wide range of finishing options, Yaotai is your go-to manufacturing partner for custom sheet metal parts, delivered on time.

Yaotai excels at producing high precision, complex parts for the most demanding applications. Contact us today and simply tell us what you need, and you can trust Yaotai to manage the whole process for you.

Sheet Metal Fabrication is a manufacturing process where sheets of metal (often steel or aluminium) are cut, folded and assembled into functional parts. The cutting of the sheet metal is achieved through the use of a laser cutting or punching process. Welding or other joining methods can be used to join parts to create complex assemblies.

Yaotai has been producing custom sheet metal parts for many years, delivering high precision, complex parts to clients from a vast range of industries. Careful design considerations are required when designing for sheet metal parts and Yaotai offers expert Design for Manufacture feedback for all quotations.

With a wide variety of secondary processes including CNC Machining and Welding, so you can complete your entire project with Yaotai

Choose Yaotai and our partner factories to successfully deliver your sheet metal project on time, to specification and without added complication.Yaotai’s ISO 9001 certification ensures high-quality sheet metal parts.

With no Minimum Order Quantity (MOQ), Yaotai provides the flexibility and scalable capacity that your project requires.

To learn more about our precision sheet metal fabrication services, Get in touch with our sales team to discuss your requirements.

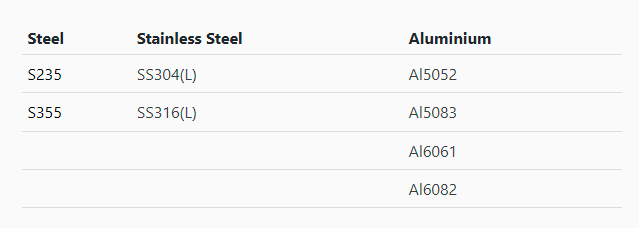

Please see our list of common metals we use to create Sheet Metal Parts. If you require a material not listed, get in touch with our expert team to discuss your requirements.

Aluminium is the most common material for high-pressure die casting, however, we can also cast Magnesium and Zinc. If you require a specific grade not listed here, please do contact us to discuss your requirements.

Product detail pictures:

Related Product Guide:

Our progress depends around the innovative machines, great talents and consistently strengthened technology forces for Short Lead Time for Metal Tumbling Machine - Aluminum OEM Stamping Sheet Metal Fabrication Part For Telecom – Yaotai , The product will supply to all over the world, such as: Haiti, Cyprus, Indonesia, Customer satisfaction is our first goal. Our mission is to pursue the superlative quality, making continual progress. We sincerely welcome you to make progress hand in hand with us, and construct a prosperous future together.

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.